One of our longtime dreams has been to provide our own energy. We’d really like to produce as much as we use, and between heating the place with the masonry heater, using wood we cut ourselves, and our new solar panels, this is likely to be the case.

Early last summer (Summer 2014), we decided we’d better get moving on the solar array. There is currently a 30% federal tax credit (not a deduction, a credit) for many types of solar systems. In addition, there are net metering laws in Michigan that make it worthwhile to tie to the electrical grid – basically, we bank credits during the long, sunny days of summer, and use those credits during the short, gray winter days. As solar becomes more common in the U.S., there also seems to be political backlash against it (apparently not everyone loves the sun!), so it seemed prudent to take advantage of the incentives while they are available.

In the interest of saving time, especially since I was out of commission for months following my foot surgery, we decided to contract out the solar electric work. A local outfit, Blue Terra Energy, has done a number of installs and had a good reputation, so we asked the owner, Dave Camps, to give us a quote. We had done a lot of research and know pretty much what we wanted – two pole-mounted arrays even with the front of the house, between the house and the fenced garden. This area has great sun exposure and a little too much slope to use as garden. Also, it’s close to the house, particularly the utility room, which makes running the electrical cabling a lot easier.

Dave Camps’ crew started by digging a couple of holes below the frostline, putting massive sonotubes in each, and putting concrete reinforcement bar (rebar) inside the tubes. Next, they lowered the poles (8″ diameter!) into the tubes, staking them so they stayed level:

Next, concrete. Those tubes are 42 inches in diameter. You can imagine how much wind those arrays catch, so this did not seem like overkill.

Since we designed our house for passive solar gain, there is very little south-facing roof. Because of this, pole-mounted arrays made more sense, even though they are more expensive due to the foundation work. The next step was the racking and the modules (aka panels):

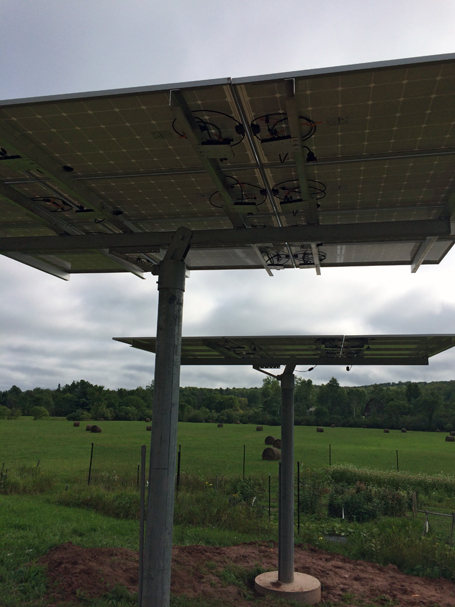

Finally, the Blue Terra crew installed the inverters and the wiring from the array to the main panel in the house. Inverters convert the DC voltage from the modules into AC that your house wiring uses. For many years, all of the modules would be connected to a single large inverter, but over the last five or ten years, micro-inverters have become available (and popular). They allow a system to be more flexible and allow for easier growth. They also make it possible to monitor each module individually, making troubleshooting easier. Below, you can see an inverter mounted underneath each module:

The system went live September 9, 2014. We tried to size the array to provide approximately the same amount of electricity in the course of a year as Nerdwood uses. Since net metering does not require the power company to pay us for any electricity we produce in excess of what we use, it does not make sense to overproduce, at least from a narrow economic perspective. As of late May, 2015, it looks like we’ll be right on target.

It’s a blast to check the metering system and see the power flowing to the grid on a sunny day. Since we live in a northerly climate, many folks around here don’t realize that solar power is more than viable, and as the price of electricity continues to climb, it seems more and more silly not to take advantage of it.